Embedded systems are the backbone of modern aerospace technology. They perform critical tasks in aircraft and spacecraft. These systems ensure safety and efficiency in aerospace operations.

Flight control systems depend on embedded systems for real-time data processing. This is crucial for decision-making during flights. Aerospace electronics, from navigation to communication, rely heavily on these systems.

The development of embedded systems in aerospace is rigorous. It involves extensive testing and validation. This ensures they meet strict safety standards.

Advancements in microelectronics have revolutionized embedded systems. They are now more powerful and compact. This enhances the performance and capabilities of aerospace technology.

Embedded systems are essential for the future of aerospace. They support innovation and drive technological progress.

The Role of Embedded Systems in Aerospace

Embedded systems play a crucial role in modern aerospace. They are responsible for executing specific tasks with high precision. These systems ensure easy operation in both aircraft and spacecraft.

Aerospace applications rely heavily on these systems. They provide the necessary functions to maintain control and safety. Their integration is vital for executing complex aerospace missions.

The tasks that embedded systems perform in aerospace are varied.

Some key functions include:

- Real-time data processing for flight operations

- Managing navigation and communication systems

- Controlling environmental systems on board

Embedded systems are designed to withstand harsh conditions. They must operate reliably under severe temperatures and pressures. This ensures continued performance without failure.

The use of embedded systems extends to unmanned aerial vehicles (UAVs) as well. In UAVs, they enable advanced functions such as autonomous flight and monitoring. This extends their importance within the aerospace sector.

As aerospace technology evolves, the role of embedded systems will continue to grow. They are pivotal to the industry's expansion and innovation. By enhancing safety and efficiency, they propel the aerospace industry into the future.

Key Components: Flight Control Systems and Aerospace Electronics

Flight control systems form the backbone of aircraft operation. They rely extensively on embedded systems for real-time data analysis and execution. These systems are vital to maintaining stability and navigational accuracy.

Aerospace electronics encompass a wide array of systems. From avionics to communication networks, their integration is essential. Each component must work in unison to ensure safe aerospace operations.

Key components of aerospace electronics include:

- Navigation systems for precise routing

- Communication systems for pilot-to-ground interactions

- Environmental controls for maintaining cabin conditions

Flight control systems execute complex maneuvers with precision. Embedded systems make quick decisions based on real-time data. This capability enhances both safety and performance.

Aerospace electronics must withstand the rigors of high-altitude operation. They are built to resist electromagnetic interference and other disturbances. This robustness ensures continued functionality under challenging conditions.

Embedded systems in these components are always evolving. Advances in software and hardware technologies drive these improvements. They allow for greater capabilities and integration within aircraft.

As aerospace technology advances, these key components will evolve too. They represent the cutting edge of innovation in aerospace applications. Their development is crucial to the future of aviation and space travel.

Safety-Critical and Real-Time Requirements

Safety-critical systems in aerospace demand uncompromising precision. They perform essential functions where failure is not an option. The impact of these systems extends beyond individual components to the entire aircraft.

Embedded systems in aerospace must operate in real-time. This means processing data and executing commands within milliseconds. Delays can lead to severe consequences, affecting overall safety.

Core requirements for safety-critical systems include:

- Fault tolerance for mitigating potential failures

- High reliability to ensure continuous operation

- Redundancy to provide backup under unexpected conditions

Real-time operating systems (RTOS) are often utilized. They prioritize tasks based on urgency, ensuring timely execution. This priority management is crucial for maintaining aircraft stability and safety.

Regulatory bodies mandate rigorous standards for these systems. Certification processes ensure that safety-critical and real-time requirements are met. Compliance is non-negotiable, securing the trust placed in aviation technology.

Safety-critical systems are central to the aerospace industry. They assure passengers and pilots of safe journeys. As technology advances, so too will the capabilities of these indispensable systems.

Design and Development Challenges

Designing embedded systems for aerospace applications poses unique challenges. These systems must meet stringent requirements for performance and reliability. The integration process requires careful planning due to the complexity involved.

Aerospace embedded systems need to operate efficiently under harsh conditions. Engineers must account for temperature fluctuations, pressure changes, and electromagnetic interference. These environmental factors demand robust and resilient designs.

Key challenges include:

- Balancing performance with power consumption

- Ensuring compatibility with existing aerospace systems

- Adhering to strict weight and space constraints

Collaboration across disciplines is crucial in aerospace design. Engineers from electronics, software, and mechanical domains work together. This teamwork ensures that all aspects are addressed and solutions are feasible.

Innovation drives the design and development of embedded systems. Continuous advancements are necessary to overcome these challenges. Engineers must stay ahead of technology trends to implement cutting-edge solutions.

Testing, Validation, and Certification Standards

Testing and validation are critical in aerospace embedded systems development. These systems must adhere to rigorous safety and reliability standards. Proper validation ensures that systems perform as intended under all conditions.

Certification is a mandatory step in the aerospace industry. Standards like DO-178C for software are essential. These frameworks ensure compliance with safety-critical requirements.

Key focus areas include:

- Thorough testing under extreme conditions

- Compliance with international aerospace standards

- Continuous monitoring for performance and safety

The testing phase involves various methodologies to verify functionality. Engineers use simulation and modeling to predict system behavior. Real-world testing follows to confirm theoretical results.

Validation processes are detailed and comprehensive, entailing both hardware and software. They aim to detect any potential failures before deployment. By doing so, they secure the safety and reliability of the final product.

Reliability, Redundancy, and Environmental Considerations

Reliability is paramount in aerospace embedded systems. A single failure can lead to catastrophic consequences. Therefore, these systems are designed with utmost care to ensure consistent performance.

Redundancy is a core strategy for maintaining system reliability. This involves implementing duplicate components and subsystems. In the event of a failure, the redundant systems take over, preventing mishaps.

Environmental conditions these systems must withstand include:

- Extreme temperatures

- High-pressure variations

- Vibrations and shock

Environmental resilience is another critical factor. Aerospace systems must operate under extreme and fluctuating conditions. They are often built with materials that withstand temperature extremes and mechanical stress.

Designers prioritize these environmental considerations during system development. The aim is to prevent failures due to external factors. This foresight ensures that the systems remain functional and reliable throughout their operational lifespan.

Advances in Embedded Systems: AI, Machine Learning, and Connectivity

In recent years, embedded systems in aerospace have seen significant advancements. Among these are the integration of artificial intelligence and machine learning. These technologies promise to enhance system performance and decision-making capabilities.

The use of AI and machine learning allows for more sophisticated data analysis. It aids in predictive maintenance by identifying potential issues before they occur. This proactive approach leads to improved safety and efficiency.

Key advancements include:

- Enhanced data processing

- Improved predictive maintenance

- Advanced diagnostics

Connectivity advancements have also reshaped aerospace systems. IoT and cloud computing facilitate real-time data sharing between devices. This connectivity improves the overall responsiveness and functionality of aerospace operations.

The convergence of AI, machine learning, and connectivity is transforming the aerospace industry. These technologies are paving the way for more autonomous and intelligent systems. They offer endless potential for future innovations in aerospace applications.

Cybersecurity in Aerospace Embedded Systems

In aerospace, cybersecurity is a critical concern due to the complexity and sensitivity of embedded systems. Protecting systems from cyber threats is essential to ensure safe and uninterrupted operations. As these systems become more interconnected, they become more vulnerable to potential attacks.

Safeguarding embedded systems in aerospace requires a multi-layered approach. This involves stringent security protocols to protect against unauthorized access and data breaches.

Essential cybersecurity measures include:

- Regular software updates

- Robust encryption methods

- Continuous monitoring

Collaboration among industry players is vital for enhancing cybersecurity. Sharing best practices and threat intelligence helps fortify defenses. By staying ahead of evolving threats, the aerospace sector can maintain the integrity and reliability of its systems.

Future Trends and Innovations

The aerospace industry constantly evolves, embracing new trends and innovations. Embedded systems are at the forefront of this progress, driving technological advancements. One major trend is the integration of artificial intelligence, which enhances decision-making and system efficiencies.

Emerging technologies like machine learning and advanced analytics are set to transform aerospace operations. These innovations promise increased automation, improved safety, and operational cost reductions.

Key trends shaping the future:

- Use of artificial intelligence

- Development of smart sensors

- Expansion of connectivity options

The potential of embedded systems in aerospace is vast. As technology progresses, these systems will continue to reshape the industry's landscape, unlocking new possibilities in aviation and space exploration.

The Expanding Impact of Embedded Systems in Aerospace

Embedded systems are critical to aerospace advancements. Their role is expanding, powering next-gen technologies and enhancing operational efficiencies. As these systems evolve, they enable safer, more reliable, and efficient flight operations.

With continuous innovation, embedded systems drive the future of aerospace. They support emerging technologies, paving the way for novel solutions and capabilities. The aerospace industry relies on these systems to maintain growth and progression, ensuring that the skies remain open to groundbreaking possibilities.

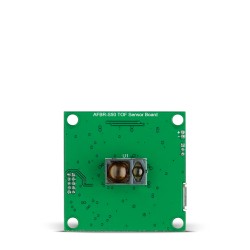

MODULAR HARDWARE FOR AEROSPACE-READY EMBEDDED SYSTEMS

In aerospace, reliability, precision, and adaptability aren't just nice to have - they’re essential. That’s where MIKROE’s Click boards™ and companion products come in. The modular boards showcased below are purpose-selected to support key aerospace functionality: gyroscopes and accelerometers for inertial navigation, environmental sensors for cabin or system monitoring, secure communication interfaces, and robust power management.

Engineers can easily integrate these components using standardized mikroBUS™ sockets, enabling the rapid prototyping of redundantly safe flight controls, telemetry systems, and sensor arrays. With these modular tools, aerospace developers gain the flexibility to iterate and qualify designs efficiently - even when failure is not an option.

EMBEDDEDWIKI PROJECTS FOR HIGH-STAKES USE CASES

To bridge the gap between concept and flight-ready hardware, explore EmbeddedWiki, our curated project repository. Here, you’ll find detailed examples of mission-critical aerospace applications built with the same Click boards featured in this blog. From autonomous drone stabilization and environmental control systems to fault-tolerant sensor networks, these guides include full documentation, schematics, and code - tailored to rigorous embedded standards.

EmbeddedWiki offers an invaluable resource for engineers aiming to prototype, validate, and deploy aerospace-grade embedded systems using modular hardware.

ABOUT MIKROE

MIKROE is committed to changing the embedded electronics industry through the use of time-saving industry-standard hardware and software solutions. With unique concepts like Remote Access, One New Product/Day, Multi-Architectural IDE and most recently, the EmbeddedWiki™ platform with more than million ready-for-use projects, MIKROE combines its dev boards, compilers, smart displays, programmers/debuggers and 1850+ Click peripheral boards to dramatically cut development time. mikroBUS™; mikroSDK™; SiBRAIN™ and DISCON™ are open standards and mikroBUS only has been adopted by over 100 leading microcontroller companies and integrated on their development boards.

Your MIKROE