The world of robotics is evolving at a rapid pace. This evolution is largely driven by advancements in embedded systems.

Embedded systems are specialized computer systems designed for specific tasks. They are integral to the functioning of modern robots.

One significant trend in this field is the use of modular embedded hardware. This approach allows for flexibility and customization in robotics design.

This article will delve into how modular embedded hardware is shaping the future of robotics. We will explore its impact on industrial robotics solutions, robotic process automation, and robotics programming.

Whether you're a robotics enthusiast, an engineer, or a business owner, this article will provide valuable insights. Stay tuned to learn about the exciting developments in robotics and embedded systems.

Introduction to Robotics and Embedded Systems

Robotics and embedded systems are two intertwined technologies propelling automation and innovation. Understanding their interplay helps grasp the foundation of modern robotic solutions.

Robotics involves designing, building, and operating robots. These machines perform tasks that are often challenging or impossible for humans. Robotics spans numerous fields, from manufacturing to healthcare, driving efficiency and precision.

Embedded systems are compact computers integrated into various devices. These systems are tailored for specific functions within larger systems. They are the silent workhorses powering many technological advancements today.

In robotics, embedded systems serve as the brains of the operation. They manage crucial functions like sensory input, data processing, and mechanical control. This allows robots to interact intelligently with their environment.

Embedded systems in robotics have undergone significant evolution. This evolution has unlocked new capabilities for robots, making them more adaptable and responsive.

The integration of embedded systems with robotics offers substantial benefits. It enhances processing power and streamlines operations, enabling robots to execute complex tasks more effectively.

As embedded systems become increasingly modular, their impact on robotics intensifies. Modular hardware architectures offer customizable solutions, allowing designers to tailor robots for specific applications.

This customization leads to improved performance and functionality across diverse environments. It supports the creation of scalable robotic solutions adaptable to different industries and needs.

Such advancements highlight the importance of embedded systems in modern robotics. By understanding this relationship, industry players can leverage these technologies for transformative industrial robotics solutions.

As we explore further, the synergy between robotics and embedded systems becomes evident. It represents a future where automation continues to grow, fueled by intelligent design and innovation.

The Importance of Modular Embedded Hardware

Definition of Modular Embedded Hardware

Modular embedded hardware refers to compact, interchangeable units designed for specific tasks. Unlike traditional embedded systems, these units offer the flexibility of rearrangement and customization. Each module can be an independent component, such as a processing unit, sensor, or communication interface.

This modularity allows the creation of highly adaptable systems. Users can reconfigure systems by swapping modules to suit varying applications. Modular designs follow a plug-and-play philosophy, facilitating easy upgrades and maintenance. The hardware's uniformity across modules ensures consistent integration, minimizing compatibility issues.

Modular embedded hardware epitomizes scalability. Adding or removing components aligns with evolving technological requirements. This approach significantly benefits industries requiring rapid iterations and adaptations of robotics solutions. Such flexibility plays a pivotal role in addressing unique application demands across different sectors.

Overall, modular embedded hardware defines the future of robotics by promoting versatility and efficiency.

Benefits of Modularity in Robotics

Modularity introduces several advantages to robotics, chief among them being versatility. It allows for swift reconfiguration of robotic systems to meet specific operational goals. This enhances the ability of robots to adapt to new challenges without significant redesigns.

Flexibility is another key benefit modularity offers. It enables robots to be tailored for various tasks across diverse environments. This customization leads to optimized performance, particularly in industries with unique or changing needs. For example, in manufacturing, the modular approach facilitates easy modification for different product lines.

Cost-effectiveness is also boosted significantly through modular design. Organizations save resources by upgrading individual modules instead of replacing entire systems. This reduces the overall lifecycle cost of robotic solutions. Not only does this make innovation more accessible, but it also promotes a sustainable approach to technology development.

Modular robotics enhance rapid prototyping, accelerating the journey from concept to functional deployment. This approach supports quick testing and iterative improvement, crucial for maintaining competitive edges in technology sectors.

Furthermore, modular embedded hardware advances innovation by lowering the entry barriers for developers. Open-source platforms and community-driven initiatives promote collaborative development. This encourages experimentation, thereby fostering cutting-edge solutions in robotic technology.

Security and maintenance are simplified with modular designs, as specific modules can be isolated for updates or troubleshooting. This isolation minimizes downtime and maintains operational integrity.

Finally, the modular approach enhances learning and educational pursuits. Modular kits provide hands-on experience with assembling and understanding complex robotic systems, fostering the next generation of tech innovators.

Altogether, modularity in robotics stands as a significant driver of innovation, adaptability, and efficiency, reflecting a dynamic future for technological applications.

Embedded Hardware in Robotics

Key Components of Embedded Systems

Embedded systems in robotics comprise crucial components that perform specific roles. At their core, microcontrollers and microprocessors drive these systems. They execute complex algorithms and processes, controlling robotic actions with precision.

Sensors represent another vital component, capturing data about the robot's environment. These sensors range from simple touch sensors to advanced vision systems. Their data guides robotic decisions, enhancing awareness and adaptability.

Actuators are integral to embedded systems, converting energy into motion. In robotics, they enable limbs, wheels, or tools to perform tasks. Their precise control is essential for executing intricate mechanical operations.

Communication interfaces connect robots with external systems. They facilitate data exchange and remote control, crucial for collaborative robotic networks. Standards such as Bluetooth and Wi-Fi play prominent roles in these operations.

Memory units in embedded systems store program codes and processed data. They ensure quick access to information, vital for real-time processing. This capability is critical for maintaining efficiency in dynamic environments.

Power management units regulate energy supply across components. They ensure embedded systems operate efficiently without overconsumption, prolonging battery life. This balance is key to sustaining prolonged robotic operations.

Lastly, user interfaces help humans interact with robots. Touchscreens and indicator lights provide status updates and control options, bridging human-machine communication gaps.

Together, these key components form the backbone of embedded systems in robotics. Their integration shapes the functionality and intelligence of modern robotic systems, driving innovation across industries.

Role of Embedded Hardware in Automation

Embedded hardware is indispensable to automation, providing the intelligence and control necessary for autonomous operations. It streamlines processes, enhancing efficiency and precision in various robotic applications.

In manufacturing, embedded systems automate production lines, coordinating tasks with minimal human intervention. They execute repetitive actions with high accuracy, improving productivity and reducing errors. These systems adapt to changing conditions, ensuring consistent output quality.

In logistics, embedded hardware manages autonomous vehicles and drones. It enables these machines to navigate complex environments with real-time processing. They optimize routes and handle tasks like loading and sorting with little oversight.

Healthcare has witnessed significant automation through embedded systems. Surgical robots, powered by precise embedded hardware, perform delicate operations. These robots offer enhanced precision and control, contributing to better patient outcomes.

Agriculture benefits from automation too. Robotic systems equipped with embedded hardware assist in planting, watering, and harvesting. They monitor crop health using sensor data, applying interventions efficiently to boost yields.

In the automotive industry, embedded systems drive advancements in self-driving technologies. Autonomous vehicles rely on sensors and processors to make real-time driving decisions. They analyze vast data streams swiftly, ensuring safe navigation.

Commercial sectors experience automation as embedded hardware powers service robots and vending machines. These systems maintain stock levels and execute transactions efficiently, enhancing customer experiences.

Embedded hardware in robotics also facilitates predictive maintenance. It enables machines to monitor their health, foreseeing and addressing issues before they arise. This reduces downtimes and extends the service life of robotic solutions.

Through these diverse applications, embedded hardware plays a pivotal role in advancing automation. It continually propels industries towards greater efficiency, adaptability, and innovation.

Industrial Robotics Solutions

Applications in Manufacturing

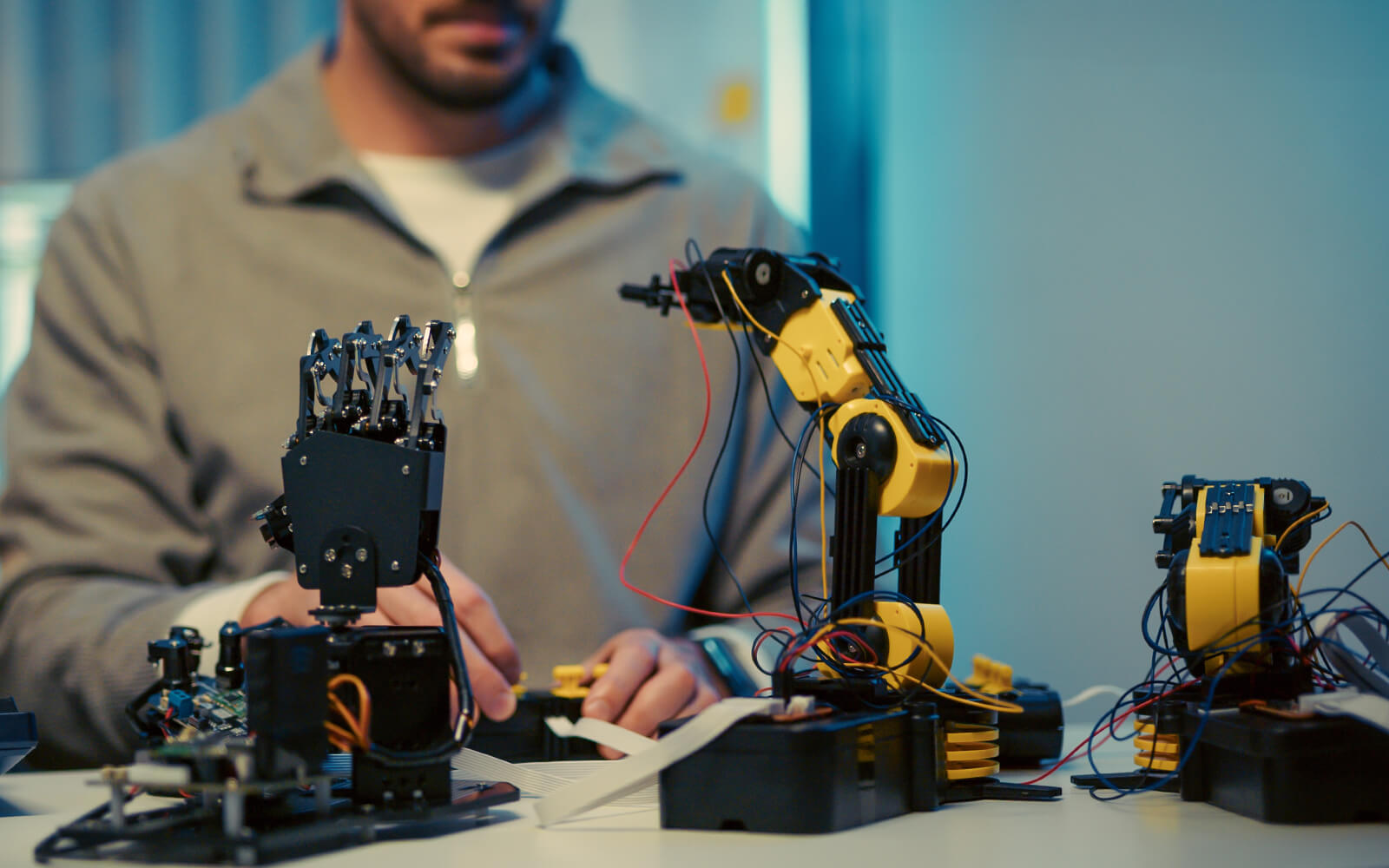

Manufacturing is a prominent area where industrial robotics shines. Automated robotic arms are ubiquitous in assembly lines. They perform repetitive tasks like welding, painting, and assembly with unmatched accuracy and speed.

CNC machines, powered by robotic technology, automate the production of complex components. They execute precise operations with minimal human input, enhancing productivity and product quality significantly.

Industrial robots also manage inventory in warehouses. They autonomously navigate storage areas, organizing and retrieving goods efficiently. This automation minimizes human error and reduces physical strain on workers.

Quality control is another critical application. Vision systems embedded within robots inspect products for defects. These systems ensure only items meeting quality standards proceed to the next production stage.

Material handling benefits greatly from robotics, too. Robots transport heavy loads across the factory floor, operating tirelessly without breaks. They optimize the flow of materials, ensuring production lines run smoothly.

In the food industry, robots perform delicate tasks like packaging and sorting. They handle perishable items with care, maintaining hygiene standards and reducing waste.

Robots are also vital in the electronics sector, assembling intricate devices. They place tiny components with precision, ensuring consistent product performance and longevity.

Customization in manufacturing is facilitated by robotics. Robots adapt quickly to different production requirements, allowing factories to switch between products seamlessly.

The integration of robotics with manufacturing boosts efficiency, reduces costs, and improves safety conditions. It enables industries to meet increasing demands and stay competitive in the global market.

Advantages of Industrial Robotics

Industrial robotics offers numerous advantages that drive its widespread adoption. Primarily, robots enhance operational efficiency and consistency in production environments. Their ability to perform tasks tirelessly means output remains stable and uninterrupted.

With robotics, businesses experience significant cost reductions. Automated systems minimize labor expenses and reduce the likelihood of costly human errors. This efficiency translates into lower overall production costs.

Safety enhancements are another key benefit. Robots handle hazardous tasks and environments that pose risks to humans. This transition reduces workplace accidents and injuries, fostering a safer work environment.

Robotics also enables companies to scale their operations with ease. As demand grows, adding more robotic systems becomes straightforward, maintaining productivity without a proportional increase in labor.

Furthermore, industrial robots provide high precision and repeatability. This ensures consistent product quality, which helps maintain customer satisfaction and brand reputation.

Modern robotics also adapt to flexible manufacturing processes. They swiftly reprogram to accommodate different tasks, allowing businesses to respond rapidly to market changes and demands.

The enhanced efficiency and flexibility offered by industrial robotics solutions keep industries competitive. These advantages are vital as companies strive to innovate and meet ever-increasing consumer expectations.

Future Trends in Industrial Automation

The future of industrial automation is poised for transformative changes. Integration with artificial intelligence will enhance robots' decision-making capabilities. AI-powered robots will autonomously adapt to complex environments and optimize processes beyond current limitations.

Collaborative robots, or cobots, represent a growing trend. These robots work alongside humans, enhancing productivity while maintaining safety. Their intuitive programming allows easy integration into existing workflows, making them ideal for small and medium enterprises.

Another trend is the Internet of Things (IoT), connecting robots within smart factories. This connectivity enables real-time data sharing and process optimization. IoT integration will further streamline operations and reduce wastage.

Sustainability in robotics is also gaining attention. Future robots will focus on energy efficiency and eco-friendly practices. Manufacturers are developing systems that consume less power and rely on sustainable materials.

5G technology is set to revolutionize industrial automation. With high-speed connectivity, robots will communicate and process data instantaneously. This will dramatically enhance coordination among robotic systems in manufacturing.

The integration of augmented reality (AR) with robotics will enhance remote monitoring and training. Workers can visualize robotic processes and receive guidance through AR interfaces, improving productivity and reducing downtime.

These future trends promise to elevate industrial automation, unlocking new potentials and efficiencies. As these technologies mature, the landscape of industrial robotics will continue to evolve, shaping the next era of manufacturing.

Robotic Process Automation

Robotic Process Automation (RPA) revolutionizes how repetitive tasks are managed across industries. By using software robots, businesses automate mundane processes. This automation enhances efficiency and reduces human error in operational workflows.

Embedded systems play a crucial role in RPA. These systems allow robots to interact with various hardware and software components seamlessly. By integrating embedded systems, RPA solutions become more robust, adaptable, and capable of handling complex tasks.

The synergy between RPA and embedded systems boosts productivity across many sectors. These technologies streamline operations by automating tasks like data entry, transaction processing, and customer interactions. As RPA technology evolves, its integration with embedded systems promises to deliver even more sophisticated automation capabilities.

Applications of RPA in Various Industries

In the financial sector, RPA has transformed operations by automating tasks such as transaction processing and compliance checks. This automation reduces the time required for financial reporting and minimizes errors, enhancing accuracy in critical tasks.

Healthcare has significantly benefited from RPA, where it streamlines patient data management and billing processes. Automating administrative tasks allows healthcare professionals to focus more on patient care, improving overall service quality.

In the retail industry, RPA optimizes inventory management and supply chain operations. Automated systems track stock levels and manage orders, ensuring timely restocks and efficient logistics.

Telecom companies utilize RPA to handle customer service operations efficiently. Bots manage service requests, perform troubleshooting, and assist with billing inquiries, enhancing customer satisfaction and reducing wait times.

The manufacturing sector leverages RPA for quality control and parts management. Automation in testing and assembly lines ensures consistency, high precision, and reduced production costs.

In human resources, RPA automates recruitment processes, screening resumes, and scheduling interviews. This reduces the administrative workload and accelerates the hiring process.

Banking institutions deploy RPA to improve loan processing and fraud detection. Automation speeds up approvals and flags suspicious activities, protecting both banks and clients.

Overall, the applications of RPA in diverse industries illustrate its versatility and the transformative impact it has on business operations.

Challenges and Limitations of RPA

Despite its advantages, RPA faces several challenges. Integrating RPA systems can be complex, requiring significant resources and planning. Organizations must ensure seamless integration with existing systems to realize the full potential of automation.

Scalability remains a concern for many businesses. While RPA can handle repetitive tasks efficiently, scaling solutions across different departments or processes may prove difficult. Each department might require tailored solutions, complicating deployment.

Another limitation is the dependency on structured data. RPA systems struggle with unstructured or inconsistent data, limiting their applicability in environments where data formats vary widely. This can pose challenges in industries where data comes in various formats.

Moreover, RPA implementation can lead to resistance among employees. Fears of job loss and changes in routine may hinder acceptance. Ensuring transparent communication and aligning RPA with human efforts can mitigate these concerns, fostering acceptance and collaboration.

Robotics Programming

Programming Languages for Robotics

Programming languages are the backbone of robotics, enabling the intricate functions of robots. Different languages serve various purposes within the robotics field. Python is widely used for its simplicity and robust libraries, making it ideal for beginners and rapid prototyping.

C++ offers control and efficiency, crucial for real-time performance. It handles complex operations required in robotics programming, often used for developing control systems and algorithms. Java plays a role in robotics, too, particularly when portability across platforms is desired. Its vast library ecosystem supports diverse robotics applications.

MATLAB is renowned for its advanced mathematical functions. It's used in developing algorithms and analyzing data, critical in robotics simulations and modeling. Meanwhile, Robot Operating System (ROS) provides a flexible framework for writing robot software, utilizing C++ and Python extensively. It allows developers to build modular robotics applications, improving collaboration across projects.

Languages like these facilitate communication with embedded hardware, ensuring robots perform tasks effectively. Understanding their strengths enables developers to select the right tools for each robotics project, pushing innovations forward.

Development Environments and Tools

Development environments are essential to robotics programming, offering tools to streamline code development and testing. Integrated Development Environments (IDEs) like Visual Studio Code and Eclipse provide powerful interfaces for coding in multiple languages. These environments support syntax highlighting, debugging, and version control, simplifying the software development lifecycle.

Simulation tools like Gazebo simulate real-world physics, allowing developers to test robotic algorithms in safe, virtual settings. This testing helps refine operations before deploying robots in real environments.

Robot Operating System (ROS) is an invaluable toolset for robotics programmers. ROS provides libraries and tools to help develop robot applications. It facilitates communication between different robotics components, ensuring seamless interoperability.

Furthermore, GitHub is widely used for version control and collaboration. Robotics developers share and manage code repositories, promoting an open-source development culture.

Using these tools, programmers enhance productivity, ensure code reliability, and foster collaborative development. This ecosystem supports the complex demands of modern robotics programming.

The Role of Software in Robotics Evolution

Software is at the heart of the robotics revolution, driving advancements and innovative solutions. It enables robots to process data, learn, and adapt to their environments. The integration of software with embedded hardware boosts robotic capabilities, making them more intelligent and autonomous.

Advanced software frameworks like ROS enable the modular design of robotics systems. This modularity allows for easier updates and maintenance, critical as technology evolves rapidly. Software also plays a vital role in robotics programming, providing algorithms and control systems that guide robotic actions.

The rise of artificial intelligence and machine learning in robotics software allows for self-learning machines. These technologies enable robots to perform complex tasks with minimal human intervention, pushing boundaries in fields like autonomous vehicles and industrial automation.

Software ensures the security of robotics systems against cyber threats. It handles encryption and authentication, securing communications between robots and controlling systems.

In essence, software not only enhances functionality but also drives innovation in the robotics industry. The continuous development of software technologies will further fuel robotics evolution, offering limitless possibilities in automating tasks and improving lives.

Conclusion

The evolution of robotics is deeply intertwined with advancements in modular embedded hardware. This synergy enhances flexibility, scalability, and affordability in robotic solutions. As robotic systems become more intricate, modular embedded systems provide the needed adaptability to meet diverse application demands.

Industrial robotics solutions are more efficient, reliable, and customizable due to this technology. The use of embedded hardware enables smarter robots with improved decision-making capabilities and real-time processing. Furthermore, advancements in robotics programming and process automation contribute to remarkable industry transformations.

The future promises continued innovation as embedded systems grow more sophisticated, pushing the boundaries of what robots can accomplish. From healthcare to manufacturing and beyond, the integration of modular systems paves the way for groundbreaking developments. By embracing these technological advances, industries can unlock new potentials, enhance productivity, and promote sustainable practices.

In conclusion, the marriage of robotics and embedded systems represents a powerful force in automating the world. This ongoing evolution holds promise for even greater achievements in the future.

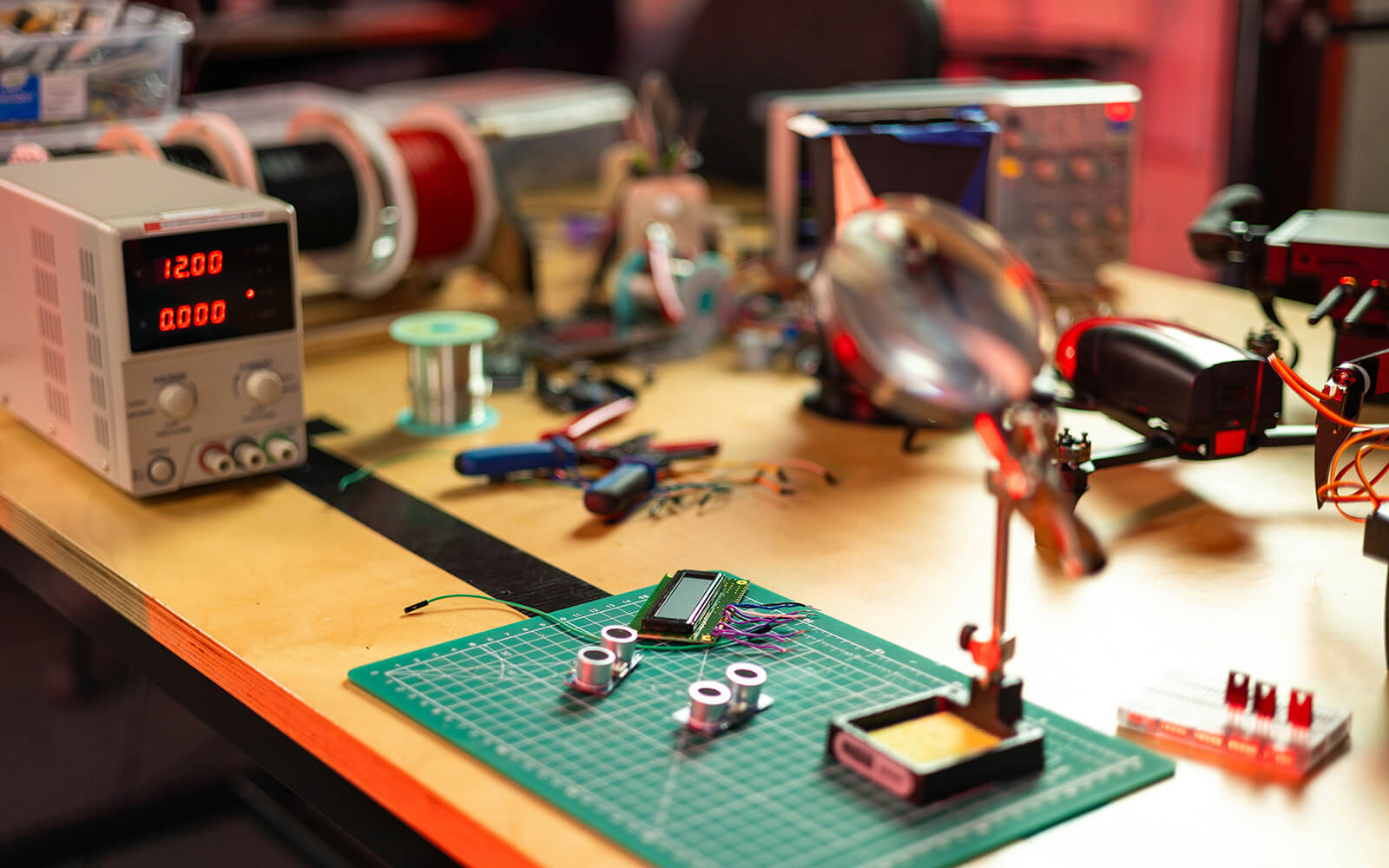

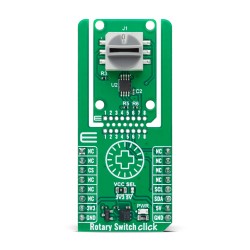

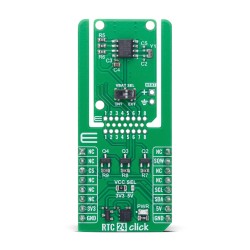

Click Boards™: The Cornerstone of Modular Design in Robotics

In robotics, adaptability and speed-to-prototype are critical. That’s where Click boards™ shine. Built on the industry-standard mikroBUS™ socket, each Click board is a self-contained module designed to perform a specific function — from sensing and motor control to wireless communication and power regulation.

With over 1850 boards in the lineup (and counting), engineers can rapidly combine multiple Click boards to build, test, and scale robotic systems — no complex wiring, no hardware redesign. Whether you're building a swarm of micro-robots or an industrial manipulator, Click boards™ provide plug-and-play flexibility that accelerates development and supports long-term modular growth.

And with NECTO Studio™, MIKROE's powerful IDE, developers can quickly prototype, debug, and deploy embedded applications for these modular systems.

Building Smarter Robots with a Click™

Each robotic subsystem — perception, control, communication, and actuation — can be built with purpose-specific Click boards. For example:

- A Sensor Click can help your robot detect its surroundings.

- A Motor Control Click provides precise movement.

- A Wireless Connectivity Click ensures seamless communication between nodes.

- A Power Management Click keeps your system efficient and protected.

In the product grid below, you'll find one representative Click board from each major subcategory — showcasing the breadth and modularity of this powerful ecosystem. By leveraging Click boards™, your robotic platform becomes agile, modular, and easily upgradable as technology evolves.

REAL-WORLD ROBOTICS PROJECTS: CLICK BOARDS™ ON EMBEDDEDWIKI

Want to see how modular embedded hardware transforms robotic systems? Dive into EmbeddedWiki, our official project hub, and explore how engineers use Click boards™ to build smarter, faster, and more adaptable robots.

From autonomous navigation and line-following bots to robotic arms and wireless control units, these projects showcase how you can mix and match Click boards™ to bring advanced robotic functionality to life — without starting from scratch.

Each guide walks you through real-world implementations using different Click board categories — helping you understand how to design modular robotic systems with real engineering impact. It’s all just a click away.

ABOUT MIKROE

MIKROE is committed to changing the embedded electronics industry through the use of time-saving industry-standard hardware and software solutions. With unique concepts like Remote Access, One New Product/Day, Multi-Architectural IDE and most recently, the EmbeddedWiki™ platform with more than million ready-for-use projects, MIKROE combines its dev boards, compilers, smart displays, programmers/debuggers and 1850+ Click peripheral boards to dramatically cut development time. mikroBUS™; mikroSDK™; SiBRAIN™ and DISCON™ are open standards and mikroBUS only has been adopted by over 100 leading microcontroller companies and integrated on their development boards.

Your MIKROE