24%

OFF

GO LOCAL

| Company | Stock | Price |

|---|---|---|

MIKROE-5303

22 g

Status:

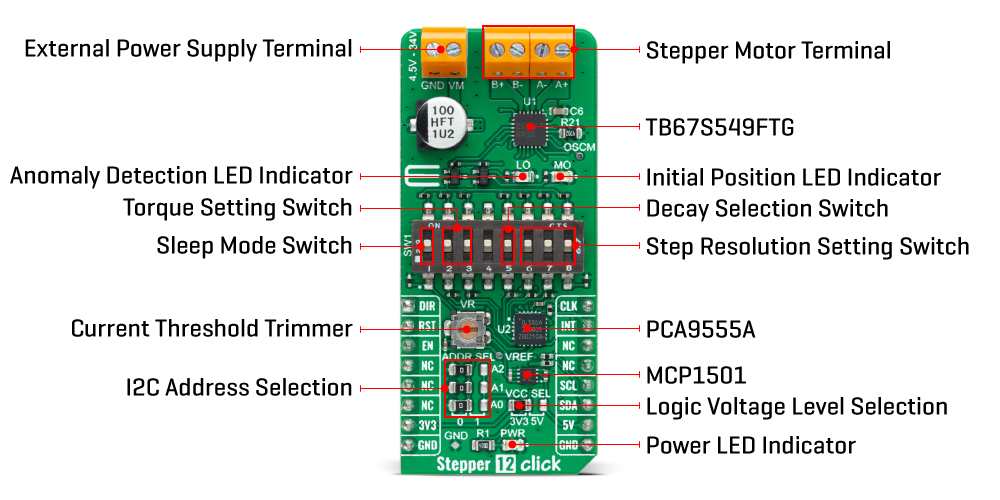

Stepper 12 Click is a compact add-on board that contains a bipolar stepper motor driver. This board features the TB67S549FTG, a two-phase bipolar stepping motor driver from Toshiba Semiconductor. It supports a PWM constant-current control drive without a current sense resistor for motor-current detection owing to the built-in function of the Advanced Current Detect System (ACDS) and allows full-step to 1/32 steps resolution for less motor noise and smoother control. It has a wide operating voltage range of 4.5V to 34V with an output current capacity of 1.5A maximum and several anomaly detection indicators. This Click board™ makes the perfect solution for small stepping motors in various applications such as office automation and commercial and industrial equipment.

Stepper 12 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

This product is no longer in stock

Availability date:

24%

OFF

| Company | Stock | Price |

|---|---|---|

Stepper 12 Click as its foundation uses the TB67S549FTG, a two-phase bipolar stepping motor driver designed to control one bipolar stepping motor with resistorless current sensing owing to the built-in function of Advanced Current Detect System (ACDS) from Toshiba Semiconductor. The TB67S549FTG incorporates low on-resistance DMOS FETs, which can deliver a 1.5A maximum current with a motor output voltage rating of 40V and integrated protection mechanisms such as over-current, over-temperature, and under-voltage lockout for error detection (LO LED indicator). It supports full-step to 1/32 steps resolution for less motor noise and smoother control, with Advanced Dynamic Mixed Decay (ADMD) built-in function that helps stabilize the current waveforms.

Thanks to the many steps that TB67S549FTG supports, motor noise can be significantly reduced with smoother operation and more precise control. It is suited to a wide range of applications such as office automation, commercial, and industrial equipment using stepping motors supporting an operational temperature range covering 40°C to +85°C. The current value in the PWM constant-current mode is set by the reference voltage value obtained by the MCP1501, a high-precision voltage regulator. Also, the current threshold point of the TB67S549FTG, alongside MCP1501, can be set manually using an onboard trimmer labeled VR.

In addition to the I2C communication, several GPIO pins connected to the mikroBUS™ socket pins are also used to forward the information to the MCU associated with the PCA9555A port expander. The PCA9555A also allows choosing the least significant bit (LSB) of its I2C slave address by positioning SMD jumpers labeled as ADDR SEL to an appropriate position marked as 0 and 1, alongside its interrupt feature routed to the INT pin of the mikroBUS™ socket.

The CLK clock signal, routed to the PWM pin of the mikroBUS™ socket, shifts the current step and electrical angle of the motor with its every up-edge, while the Enable pin, labeled as EN and routed to the CS pin of the mikroBUS™ socket, controls the state of the output A and B stepping motor drive channels. The normal constant current control is started by turning the motor drive ON (HIGH level), while by setting the motor drive OFF, the outputs are turned high impedance because the MOSFETs are set to OFF (LOW level). Besides, all circuits can be stopped using the Sleep function and thus enable power saving mode. A simple DIR pin routed to the AN pin on the mikroBUS™ socket allows MCU to manage the direction of the stepper motor (clockwise or counterclockwise), while the RST pin of the mikroBUS™ socket initializes an electrical angle in the internal counter to set an initial position. Achieving an initial position is indicated via onboard orange LED labeled as MO.

A specific addition to this Click board™ is a multifunctional switch that allows the user, by selecting a particular switch, to set appropriate features such as:

In addition to this physical way of setting these functions, the user can select them digitally via the I2C interface.

The Stepper 12 Click supports an external power supply for the TB67S549FTG, which can be connected to the input terminal labeled as VM and should be within the range of 4.5V to 34V, while the stepper motor coils can be connected to the terminals labeled as B+, B-, A-, and A+.

This Click board™ can operate with both 3.3V and 5V logic voltage levels selected via the VCC SEL jumper. This way, it is allowed for both 3.3V and 5V capable MCUs to use communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Type

Stepper

Applications

Can be used for small stepping motors in a wide range of applications such as office automation, commercial and industrial equipment

On-board modules

TB67S549FTG - two-phase bipolar stepping motor driver with resistorless current sensing thanks to Advanced Current Detect System (ACDS) from Toshiba Semiconductor

Key Features

Low power consumption, capable of controlling one bipolar stepping motor, PWM controlled constant-current drive, operational in full, half, quarter, 1/8, 1/16, and 1/32 step resolutions, built-in a mixed decay mode, anomaly detection functions, and more

Interface

GPIO,I2C

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

L (57.15 x 25.4 mm)

Input Voltage

3.3V or 5V,External

This table shows how the pinout on Stepper 12 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| LD2 | L0 | - | Anomaly Detection LED Indicator |

| LD3 | M0 | - | Initial Position LED Indicator |

| JP1-JP3 | ADDR SEL | Left | I2C Address Selection 0/1: Left position 0, Right position 1 |

| JP4 | VCC SEL | Left | Logic Level Voltage Selection 3V3/5V: Left position 3V3, Right position 5V |

| SW1 | POS 1 | Middle | Sleep Mode Activation Switch |

| SW1 | POS 2-3 | Middle | Motor Torque Setting Switch |

| SW1 | POS 5 | Middle | Mixed Decay Control Switch |

| SW1 | POS 6-7-8 | Middle | Step Resolution Setting Switch |

| VR | VR | - | Current Threshold Trimmer |

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage VCC | 3.3 | - | 5 | V |

| External Supply Voltage VM | 4.5 | 24 | 34 | V |

| Maximum Output Voltage | - | - | 40 | V |

| Maximum Output Current | - | - | 1.5 | A |

| Maximum Step Clock Frequency | - | - | 250 | kHz |

| Operating Temperature Range | -20 | +25 | +85 | °C |

We provide a library for the Stepper 12 Click as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

Package can be downloaded/installed directly from NECTO Studio Package Manager(recommended way), downloaded from our LibStock™ or found on Mikroe github account.

Library Description

This library contains API for Stepper 12 Click driver.

Key functions

stepper12_set_direction This function sets the motor direction by setting the DIR pin logic state.

stepper12_drive_motor This function drives the motor for the specific number of steps at the selected speed.

stepper12_set_step_mode This function sets the step mode resolution settings.

Example Description

This example demonstrates the use of the Stepper 12 Click board™ by driving the motor in both directions for a desired number of steps.

void application_task ( void )

{

log_printf ( &logger, " Move 200 full steps clockwise rnn" );

stepper12_set_step_mode ( &stepper12, STEPPER12_MODE_FULL_STEP );

stepper12_set_direction ( &stepper12, STEPPER12_DIR_CW );

stepper12_drive_motor ( &stepper12, 200, STEPPER12_SPEED_FAST );

Delay_ms ( 2000 );

log_printf ( &logger, " Move 400 quarter steps counter-clockwise rnn" );

stepper12_set_step_mode ( &stepper12, STEPPER12_MODE_QUARTER_STEP );

stepper12_set_direction ( &stepper12, STEPPER12_DIR_CCW );

stepper12_drive_motor ( &stepper12, 400, STEPPER12_SPEED_FAST );

Delay_ms ( 2000 );

}

The full application code, and ready to use projects can be installed directly from NECTO Studio Package Manager(recommended way), downloaded from our LibStock™ or found on Mikroe github account.

Other Mikroe Libraries used in the example:

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MikroElektronika compilers.

This Click board™ is supported with mikroSDK - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

NOTE: Please be advised that any peripheral devices or accessories shown connected to the Click board™ are not included in the package. Check their availability in our shop or in the YMAN section below.