50%

OFF

GO LOCAL

| Company | Stock | Price |

|---|---|---|

MIKROE-3814

20 g

Status:

The Peltier Click is a Click board™ which utilizes the SPV1050, an ultralow power energy harvester and battery charger from STMicroelectronics. The Peltier click can charge lithium battery using thermoelectric energy harvesting device (TEG). A TEG converts heat directly into electrical energy according to the Seebeck effect. It can be used for a variety of applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness.

The Peltier click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

The Peltier element is not included in the Click board package, if you want to by one visit our Peltier Element TEC1-12706 product page.

This product is no longer in stock

Availability date:

50%

OFF

| Company | Stock | Price |

|---|---|---|

The Peltier click is based on the SPV1050, an ultralow power energy harvester and battery charger from STMicroelectronics that can charge lithium based batteries. A thermoelectric harvester produces green energy for energy harvesting with a multitude of advantages: maintenance-free, because of the use of highly reliable and compact solid-state device; silent and quiet; highly efficient in environmental terms because the heat is harvested from waste heat sources and converted into electricity. Because of this feature, the Peltier click can be used for a variety of applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness.

The SPV1050 is an ultralow power and highefficiency energy harvester and battery charger, which implements the MPPT function and integrates the switching elements of a buck-boost converter. The SPV1050 device allows the charge of lithium battery, by tightly monitoring the end-of-charge and the minimum battery voltage in order to avoid the overdischarge and to preserve the battery life. The power manager is suitable for TEG harvesting sources, as it covers the input voltage range from 75 mV up to 18 V and guarantees high efficiency in both buck-boost and boost configuration.

Furthermore the SPV1050 device shows very high flexibility thanks also to the trimming capability of the end-of-charge and undervoltage protection voltages. In such way any source and battery is matched. The MPPT is programmable by a resistor input divider and allows maximizing the source power under any temperature and irradiance condition.

Some of the key features of the SPV1050 are its transformerless thermoelectric generators and PV modules energy harvester, high efficiency for any harvesting source and it has up to 70 mA maximum battery charging current. It is fully integrated buck-boost DC-DC converter with a programmable MPPT by external resistors, 2.6 V to 5.3 V trimmable battery charge voltage level (± 1% accuracy), 2.2 V to 3.6 V trimmable battery discharge voltage level (± 1% accuracy) with two fully independent LDOs (1.8 V and 3.3 V output). The SPV1050 can enable/disable LDO control pins and it has a battery disconnect function for battery protection, and while the battery is connected and ongoing charge logic open drain indication pins.

The SPV1050 is basically an ultralow power energy harvester with an embedded MPPT algorithm, a battery charger and power manager designed for applications up to about 400 mW.

Type

Battery charger

Applications

Variety of applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness

On-board modules

SPV1050, an ultralow power energy harvester and battery charger from STMicroelectronics

Key Features

Charge any battery type, including lithium based, solid state thin film and super-capacitor, 3.3v input voltage

Interface

GPIO

Feature

No ClickID

Compatibility

mikroBUS™

Click board size

M (42.9 x 25.4 mm)

Input Voltage

3.3V

This table shows how the pinout on Peltier click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

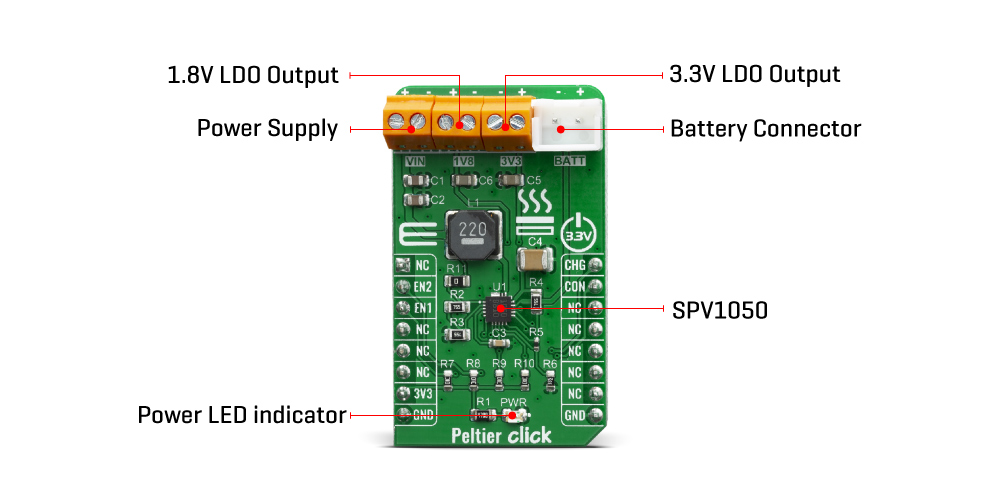

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| TB1 | VIN | - | Power Supply |

| TB2 | 1V8 | - | 1.8V LDO Output |

| TB3 | 3V3 | - | 3.3V LDO Output |

| J1 | BATT | - | Battery Connector |

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Maximum battery charging current | - | - | 70 | mA |

| BATT pin voltage range | 2.2 | 4.2 | 5.3 | V |

| MPPT tracking period | 12 | - | 20 | S |

We provide a library for the Peltier Click on our LibStock page, as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

Library Description

The library covers all the necessary functions to control Peltier Click board. Peltier Click communicates with the target board through the RST, CS, PWM and INT pins. This library offers functions for detecting the states of PWM and INT pins and for seting or clearing RST and CS pins.

Key functions:

void peltier_enableLdo2(); - Function is used to enable 3.3V output.void peltier_enableLdo1(); - Function is used to enable 1.8V output.uint8_t peltier_batteryCharge(); - Function is used to check ongoing battery charge flag pin.Examples description

The application is composed of three sections :

void applicationTask()

{

mikrobus_logWrite( " 1.8V output ", _LOG_LINE );

mikrobus_logWrite( "------------------", _LOG_LINE );

peltier_enableLdo1();

peltier_disableLdo2();

Delay_ms( 5000 );

mikrobus_logWrite( " 3.3V output ", _LOG_LINE );

mikrobus_logWrite( "------------------", _LOG_LINE );

peltier_disableLdo1();

peltier_enableLdo2();

Delay_ms( 5000 );

mikrobus_logWrite( " Both outputs ", _LOG_LINE );

mikrobus_logWrite( "------------------", _LOG_LINE );

peltier_enableLdo1();

peltier_enableLdo2();

Delay_ms( 5000 );

mikrobus_logWrite( " Disable outputs ", _LOG_LINE );

mikrobus_logWrite( "------------------", _LOG_LINE );

peltier_disableLdo1();

peltier_disableLdo2();

Delay_ms( 5000 );

}

The full application code, and ready to use projects can be found on our LibStock page.

Other mikroE Libraries used in the example:

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.

This Click board™ is supported with mikroSDK - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

For more information about mikroSDK, visit the official page.

NOTE: Please be advised that any peripheral devices or accessories shown connected to the Click board™ are not included in the package. Check their availability in our shop or in the YMAN section below.