20%

OFF

GO LOCAL

| Company | Stock | Price |

|---|---|---|

MIKROE-6712

22 g

Status:

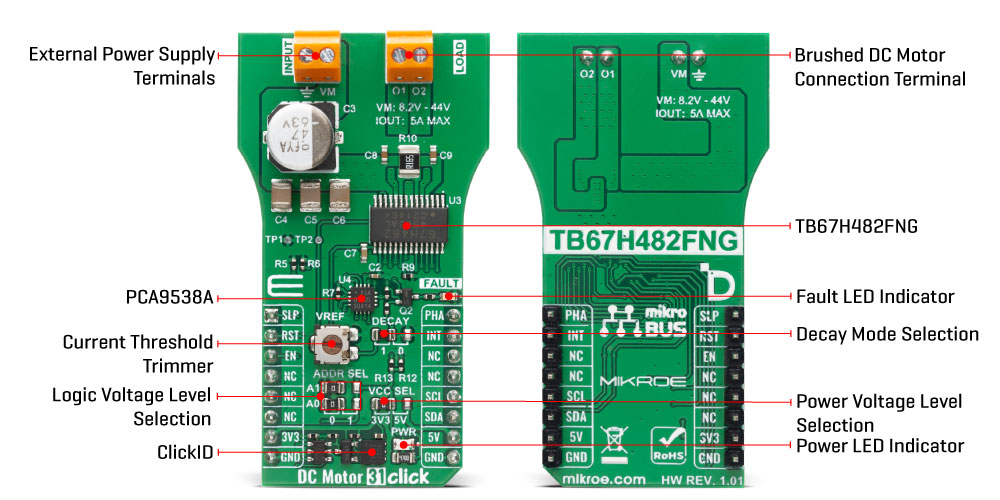

DC Motor 31 Click is a compact add-on board designed to drive brushed DC motors providing precise control, torque adjustment, and fault monitoring for a wide range of applications. It is based on the TB67H482FNG, a BiCD constant-current single H-bridge driver IC from Toshiba Semiconductor. Supporting motor supply voltages from 8.2V to 44V and output currents up to 4A, it integrates PWM constant-current drive, decay mode selection, and a trimmer for fine motor speed tuning. This Click board is an ideal solution for industrial automation, consumer devices, and robotic systems that require robust and energy-efficient brushed DC motor control.

DC Motor 31 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to automatically detect and identify this add-on board.

This product is no longer in stock

Availability date:

20%

OFF

| Company | Stock | Price |

|---|---|---|

DC Motor 31 Click is based on the TB67H482FNG, a BiCD constant-current single H-bridge driver IC from Toshiba Semiconductor. Designed for driving brushed DC motors in industrial, consumer, and robotic systems, this IC integrates a monolithic H-bridge structure where DMOSFETs are employed as output power transistors, ensuring robust performance with a maximum output current capability of up to 4A. The board supports a wide motor supply voltage range from 8.2V to 44V, made possible by the IC’s built-in regulator that allows operation from a single VM power supply. A key feature of the TB67H482FNG is its PWM constant-current drive capability, providing motor control across various loads and conditions.

To optimize performance in different application scenarios, the board includes a decay mode select function that allows users to switch between Slow Decay and Fast Decay operation via an onboard DECAY SEL jumper, offering flexibility in tuning motor response and efficiency. Fine control over the motor’s operating current is further enabled through an integrated VREF trimmer, which adjusts the reference voltage and thereby sets the current threshold, ensuring precise management of torque and speed characteristics. Additionally, the IC incorporates a comprehensive set of protection features including overtemperature detection, overcurrent protection, and undervoltage lockout, safeguarding both the driver and the connected motor against common fault conditions.

In addition to the powerful TB67H482FNG H-bridge driver, DC Motor 31 Click incorporates the PCA9538A port expander, which plays a central role in managing auxiliary control and monitoring functions of the motor driver. The PCA9538A is an 8-bit I/O expander with an I2C-bus interface, enabling the host MCU to control multiple signals through just two communication lines. One of its key responsibilities is torque control, where it manages five dedicated motor torque setting pins of the TB67H482FNG, allowing flexible adjustment of the motor’s torque characteristics directly through software commands sent over the I2C bus.

Furthermore, the PCA9538A enhances fault management by monitoring the error detection flag output of the TB67H482FNG. The port expander relays this status to the MCU while simultaneously driving a red FAULT LED on the board, ensuring both digital monitoring and a clear visual indication of detected fault conditions such as overcurrent, overtemperature, or undervoltage events. All interrupts detected by the port expander can be monitored through the INT pin. To provide flexibility in system design, the board features an ADDR SEL jumper that allows selection of the I2C address, enabling multiple devices to coexist on the same bus without conflict.

The DC Motor 31 Click also provides direct control signals that enhance system reliability and power efficiency. Among these are the RST pin, which allows the host MCU to reset the TB67H482FNG driver in case of fault conditions or during initialization, and the SLP pin is dedicated to the device’s power-saving functionality, enabling the motor driver to enter a low-power Sleep mode when the motor is not in operation. Complementing these is the EN pin, which acts as the main enable control for the TB67H482FNG, giving the MCU straightforward authority to activate or deactivate the motor driver as needed.

This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Type

Brushed

Applications

Ideal for air conditioning systems, printers, scanners, office automation, robotics, and factory automation

On-board modules

TB67H482FNG - BiCD constant-current single H-bridge driver IC from Toshiba Semiconductor

Key Features

Wide motor supply voltage, output current capability up to 4A, PWM constant-current drive, integrated Slow/Fast Decay mode, trimmer for fine motor speed adjustment, built-in protection features, I/O expander with I2C interface for torque control and fault monitoring, and more

Interface

I2C,PWM

Feature

ClickID

Compatibility

mikroBUS™

Click board size

L (57.15 x 25.4 mm)

Input Voltage

3.3V or 5V,External

This table shows how the pinout on DC Motor 31 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| LD2 | FLT | - | Fault LED Indicator |

| JP1 | VCC SEL | Left | Power Voltage Level Selection 3V3/5V: Left position 3V3, Right position 5V |

| JP2/JP4 | ADDR SEL | Left | I2C Address Selection 0/1: Left position 0, Right position 1 |

| JP3 | DECAY SEL | Left | Decay Mode Selection 1/0: Left position 1, Right position 0 |

| VR1 | VREF | - | Current Threshold Trimmer |

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | 3.3 | - | 5 | V |

| External Power Supply Voltage | 8.2 | - | 44 | V |

| Output Operating Current | - | 4 | 5 | A |

NOTE: Continuous operation near the absolute maximum current may cause excessive heating. For improved thermal management, MIKROE offers aluminum and copper heatsinks with adhesive tapes, available in our shop.

DC Motor 31 Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the operation of the DC Motor 31 Click board by alternating the motor direction between forward and reverse with braking in between.

Key Functions

dcmotor31_cfg_setup This function initializes Click configuration structure to initial values.dcmotor31_init This function initializes all necessary pins and peripherals used for this Click board.dcmotor31_default_cfg This function executes a default configuration of DC Motor 31 Click board.dcmotor31_set_mode This function sets the motor control mode to forward, reverse, or brake.dcmotor31_set_torque This function sets the output torque by writing to the OUTPUT register.Application Init

Initializes the logger and the Click board, then applies the default configuration.

Application Task

Changes the motor direction from forward to reverse with a brake period in between, and logs the current motor state on the UART terminal.

Application Output

This Click board can be interfaced and monitored in two ways:

Additional Notes and Information

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

NOTE: Please be advised that any peripheral devices or accessories shown connected to the Click board™ are not included in the package. Check their availability in our shop or in the YMAN section below.