OFF

GO LOCAL

| Company | Stock | Price |

|---|---|---|

MIKROE-6681

32 g

Status:

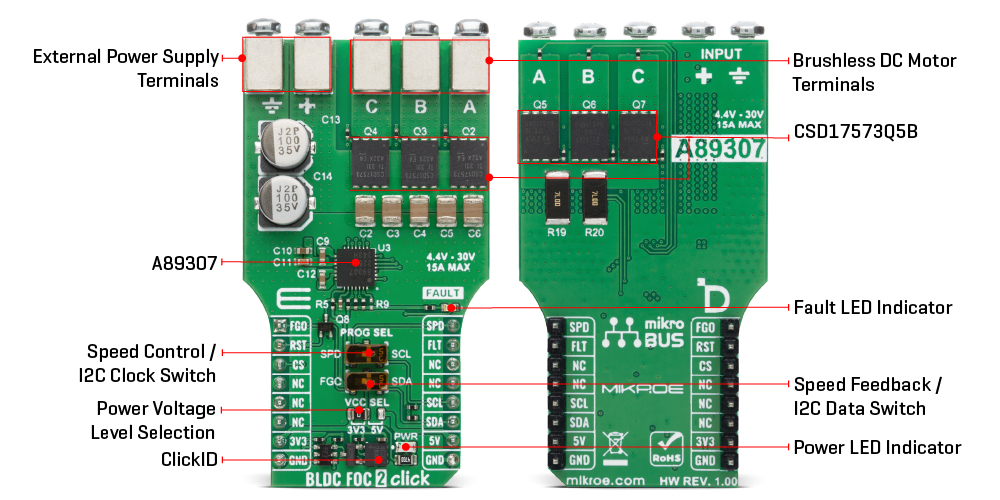

BLDC FOC 2 Click is a compact add-on board that provides control of three-phase brushless DC (BLDC) motors using advanced field-oriented control (FOC) techniques, ensuring smooth operation, high efficiency, and low acoustic noise. It is based on the A89307, an automotive FOC BLDC motor controller from Allegro Microsystems, designed to deliver up to 15A of output current across a wide voltage range from 4.4V to 30V. This Click board™ supports multiple operating modes, including constant speed, torque, power, and open-loop control, while offering flexible configuration via EEPROM and I2C interface for parameter setting, ON/OFF control, and speed feedback. It also integrates Allegro’s proprietary Soft-On Soft-Off (SOSO) feature for quiet transitions, comprehensive protection mechanisms, and both analog and digital control mode. BLDC FOC 2 Click is ideal for automotive and industrial applications such as battery cooling fans, radiator fans, and fuel or oil pump control systems.

BLDC FOC 2 Click is fully compatible with the mikroBUS™ socket and can be used on any host system supporting the mikroBUS™ standard. It comes with the mikroSDK open-source libraries, offering unparalleled flexibility for evaluation and customization. What sets this Click board™ apart is the groundbreaking ClickID feature, enabling your host system to automatically detect and identify this add-on board.

This product is no longer in stock

Availability date:

OFF

| Company | Stock | Price |

|---|---|---|

BLDC FOC 2 Click is based on the A89307, an automotive FOC BLDC motor controller from Allegro Microsystems. Designed for driving and controlling three-phase brushless DC (BLDC) motors using field-oriented control (FOC) techniques, this board uses six external N-channel power MOSFETs (CSD17573Q5B) to deliver motor currents up to 15A at operating voltages between 4.4 and 30V on the INPUT terminal. Its fully integrated sensorless FOC algorithm eliminates the need for external position sensors, simplifying design complexity while ensuring superior efficiency, torque control, and acoustic performance. With its AEC-Q100 automotive qualification and advanced performance characteristics, BLDC FOC 2 Click provides an ideal solution for automotive and industrial applications requiring efficient, quiet, and reliable motor control, such as battery cooling fans, radiator fans, and fuel or oil pumps.

The controller supports multiple operating modes, including constant speed, constant torque, constant power, and open-loop modes, allowing flexible adaptation to diverse system requirements. To ensure smooth startup in all situations, it features optimized algorithms for stationary, windmill, and reverse windmill conditions, preventing reverse rotation and enabling reliable start sequences. The A89307 also implements Allegro’s proprietary Soft-On Soft-Off (SOSO) technology for ultra-quiet transitions and includes comprehensive protection mechanisms such as short-circuit protection, lock detection, and overcurrent protection, ensuring safe and stable operation.

BLDC FOC 2 Click uses a flexible control interface that allows users to select between analog and digital modes for motor speed regulation and system communication. The speed demand input is provided through the SPD pin, which supports three selectable speed control modes configurable via the onboard EEPROM. Depending on the application requirements, the user can enable or disable closed-loop functions for speed, torque, and power control through EEPROM programming, ensuring optimal motor behavior under varying operating conditions. For accurate performance, the motor’s rated current at its nominal speed and normal load must be stored in the EEPROM, allowing the A89307 controller to execute precise field-oriented control and maintain stability during dynamic load transitions.

The SPD pin also serves a dual purpose: in I2C communication mode, it functions as the serial clock line (SCL), while the FGO pin, normally an open-drain output providing tachometer feedback to the system, acts as the serial data line (SDA). Through this I2C interface, users can configure key motor parameters such as rated voltage, rated current, rated speed, winding resistance, and startup profiles, while also performing ON/OFF control, real-time speed adjustments, and speed readback operations. To accommodate this dual functionality of the SPD and FGO pins, BLDC FOC 2 Click includes a PROG SEL switch that allows manual selection between analog control and I2C mode by setting both switches to the corresponding position.

This Click board™ also provides directional and fault management features to ensure reliable and safe motor operation under various conditions. The CS pin, which also serves as a directional control input, is used to control the motor’s rotational direction, where a logic HIGH level sets the phase commutation sequence to A-B-C, and a logic LOW level reverses the order to A-C-B. In addition to hardware control, the direction of rotation can also be configured through internal registers using the I2C interface, allowing software-based direction management within automated or adaptive control systems.

Fault monitoring is handled by the FLT pin, which operates as an open-drain output providing real-time fault status information to the system controller. The FAULT signal follows a specific pattern defined in the A89307 datasheet, where each fault type corresponds to a unique signal behavior, and priority handling ensures that when multiple fault conditions occur simultaneously, the highest-priority fault is reported. For enhanced user feedback, this fault condition is also visually indicated by the onboard red FAULT LED, allowing quick and intuitive diagnostics during testing, setup, or runtime operation.

This Click board™ can operate with either 3.3V or 5V logic voltage levels selected via the VCC SEL jumper. This way, both 3.3V and 5V capable MCUs can use the communication lines properly. Also, this Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used as a reference for further development.

Type

Brushless

Applications

Ideal for automotive and industrial applications such as battery cooling fans, radiator fans, and fuel or oil pump control systems

On-board modules

A89307 - automotive FOC BLDC motor controller from Allegro Microsystems

Key Features

Sensorless field-oriented control (FOC) algorithm, wide operating voltage range, up to 15A output current capability, multiple operating modes including constant speed, constant torque, constant power, and open-loop, EEPROM-configurable closed-loop speed, torque, and power control, I2C interface for configuration, ON/OFF control, and speed feedback, programmable motor parameters, Soft-On Soft-Off (SOSO) technology for ultra-quiet operation, protection features, and more

Interface

Analog,I2C,PWM

Feature

ClickID

Compatibility

mikroBUS™

Click board size

L (57.15 x 25.4 mm)

Input Voltage

3.3V or 5V,External

This table shows how the pinout on BLDC FOC 2 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| LD2 | FAULT | - | Fault LED Indicator |

| JP1 | VCC SEL | Left | Power Voltage Level Selection 3V3/5V: Left position 3V3, Right position 5V |

| SW1 | PROG SEL | Left | Speed Control / I2C Clock SPD/SCL: Left position SPD, Right position SCL |

| SW2 | PROG SEL | Left | Speed Feedback / I2C Data FGO/SDA: Left position FGO, Right position SDA |

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | 3.3 | - | 5 | V |

| External Power Supply | 4.4 | - | 30 | V |

| Maximum Output Current | - | - | 15 | A |

BLDC FOC 2 Click demo application is developed using the NECTO Studio, ensuring compatibility with mikroSDK's open-source libraries and tools. Designed for plug-and-play implementation and testing, the demo is fully compatible with all development, starter, and mikromedia boards featuring a mikroBUS™ socket.

Example Description

This example demonstrates the control of a 3-phase brushless DC motor using the BLDC FOC 2 Click board. The motor speed is gradually increased and decreased while changing direction on each cycle. The example also includes an optional EEPROM programming step if enabled via macro.

Key Functions

bldcfoc2_cfg_setup This function initializes Click configuration structure to initial values.bldcfoc2_init This function initializes all necessary pins and peripherals used for this Click board.bldcfoc2_default_cfg This function executes a default configuration of BLDC FOC 2 Click board.bldcfoc2_eeprom_set_config This function sets the default EEPROM configuration for the motor F80 PRO KV1900, optimized for 11.2V 10A power supply and PWM input range 10-50% at 20kHz.bldcfoc2_set_duty_cycle This function sets the PWM duty cycle used to control the motor speed.bldcfoc2_switch_direction This function toggles the motor rotation direction by inverting the DIR pin state.Application Init

Initializes the logger and the Click board driver, applies the default configuration, and optionally programs the EEPROM if enabled.

Application Task

Gradually ramps the motor speed up and down, applies brake and switches direction on each full speed cycle. Speed is controlled via PWM duty cycle.

Application Output

This Click board can be interfaced and monitored in two ways:

Additional Notes and Information

The complete application code and a ready-to-use project are available through the NECTO Studio Package Manager for direct installation in the NECTO Studio. The application code can also be found on the MIKROE GitHub account.

NOTE: Please be advised that any peripheral devices or accessories shown connected to the Click board™ are not included in the package. Check their availability in our shop or in the YMAN section below.