20%

OFF

GO LOCAL

| Company | Stock | Price |

|---|---|---|

MIKROE-6795

2815 g

Status:

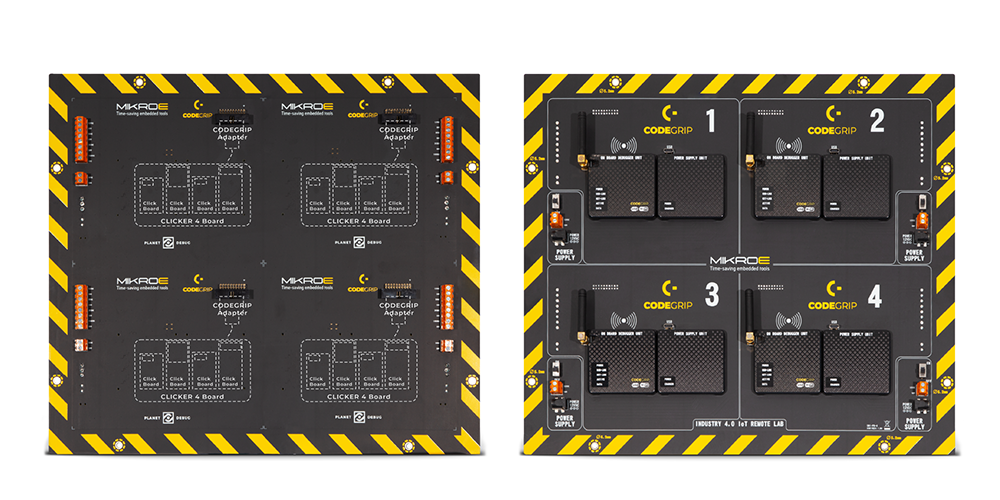

Planet Debug Backplane 4 UNI CODEGRIP unit is a hardware panel that serves as the physical mounting surface for multiple embedded setups used with MIKROE’s Planet Debug remote development service. It integrates four UNI CODEGRIP WiFi programmers/debuggers, each with its own dedicated power supply section featuring a power switch and dual 12VDC input connectors, along with regulated output voltages of 1.8V, 3.3V, and 5V. The front side is divided into four equal quadrants, each providing a dedicated area for mounting development boards such as Clicker 4, complete with independent power outputs. Unlike the single-unit version, this backplane does not include a DRILL AREA, as both sides are fully populated to maximize functionality. Acting as the foundation for multi-board setups, it enables real-time remote programming, debugging, and monitoring through the Planet Debug platform and NECTO Studio IDE, making it ideal for parallel testing, hardware validation, and advanced educational environments.

This product is no longer in stock

Availability date:

20%

OFF

| Company | Stock | Price |

|---|---|---|

The Planet Debug Backplane 4 UNI CODEGRIP unit is a dedicated hardware panel designed for mounting embedded setups that will be used within the Planet Debug service - MIKROE’s Industry 4.0 IoT Remote Lab for real-time remote embedded development. Installed on the Planet Debug frame, this backplane serves as the physical base for multiple configurations displayed and controlled remotely through the Planet Debug platform. Planet Debug itself enables engineers to interact with real hardware - development boards, sensors, actuators, and displays - as if they were physically in the lab, all from anywhere in the world. Each setup includes an actual development board and a live video camera, combined with UNI CODEGRIP WiFi debuggers (this particular backplane integrates four of them) that provide SSL-secured remote access. Through the NECTO Studio IDE, users can stream a live video feed directly from the lab and observe in real time how their code affects the physical device - whether it’s an LED blinking, a sensor value changing, or a display being refreshed. Unlike software simulators that only emulate behavior, Planet Debug gives users direct access to real hardware and peripherals, ensuring accurate feedback and reliable test results.

The Planet Debug Backplane 4 UNI CODEGRIP unit is the mounting surface where multiple hardware setups are placed and operated. On the back side of the board, it features four UNI CODEGRIP WiFi debuggers, each with its own dedicated Power Supply section. Every section includes a power switch and dual 12VDC input connectors (one standard terminal and one barrel jack) ensuring that each debugging field can be powered independently. Unlike the single-unit version, this backplane does not feature a marked DRILL AREA, as both sides of the board are fully populated with functional sections.

On the front side, the backplane is divided into four equal quadrants that mirror the arrangement on the back. Each quadrant provides a dedicated area for mounting development boards such as the Clicker 4, along with its own set of output terminals delivering regulated voltages of 1.8V, 3.3V, and 5V derived from the 12VDC supply. This structure allows four completely independent setups to be integrated and accessed remotely, while maintaining the same flexibility and secure debugging features as the single-unit version. At the very bottom of the backplane, a printed label identifies it as the official board intended for use with the Planet Debug service. This label confirms its role as an integral part of MIKROE’s remote development infrastructure, serving as the physical foundation for multi-board setups that are accessed, monitored, and controlled remotely through the Planet Debug platform.

| Parameter | Value |

|---|---|

| Input Voltage | 12V DC (via terminal connector or barrel jack) |

| Output Voltages | 1.8V / 3.3V / 5V (regulated from 12V input) |

| Power Supply Control | Independent power switch for each section |

| Integrated Debugger | 4 x UNI CODEGRIP WiFi (SSL-secured, remote debugging and programming) |

| Wireless Connectivity | WiFi, secured SSL channel |

| Mechanical Features | No DRILL AREA - both sides fully populated |