In the realm of industrial communication, the serial RS-232 standard holds a significant place. It's a protocol that has stood the test of time.

Despite the advent of newer technologies, RS-232 remains a reliable choice. It's used in a wide array of applications, from automation systems to data acquisition.

But what makes RS-232 so enduring?

This article aims to answer that question by exploring the technical aspects of RS-232 communication, including its components and protocols.

With a particular focus on industrial applications, we’ll examine why RS-232 remains a preferred choice among engineers and IT professionals. More than just a communication standard, RS-232 has shaped the way industries operate, enabling reliable data transmission even in harsh environments.

We’ll break down the anatomy of an RS-232 port—covering pin configurations, signal levels, and how the communication process works. As the RS-232 standard has evolved over the years, we’ll trace its journey, evaluate its current relevance, and explore what role it might play in the future of modern industries.

A step-by-step guide will walk through setting up RS-232 communication, explaining the different types of connectors and their use cases, along with the process for establishing a stable connection. Common issues will also be addressed, including troubleshooting tips and the impact of cable length and quality on performance.

To provide context, RS-232 will be compared with other communication standards, outlining its strengths, weaknesses, and how it can be converted to interface with newer protocols.

Legacy systems continue to rely on RS-232, especially in environments with Programmable Logic Controllers (PLCs) and automation/control systems. We’ll examine its ongoing compatibility in these setups and showcase real-world examples across industries—from manufacturing to telecommunications—highlighting successful implementations.

In the context of the Internet of Things (IoT), RS-232 still has a role to play. We’ll look at its potential applications in the evolving landscape of industrial communication.

For practical guidance, the article offers advice on choosing the right RS-232 cable for specific scenarios, emphasizes the importance of proper grounding, and outlines key security considerations to ensure data integrity.

To round things off, you’ll find a list of recommended software tools for RS-232 testing and a set of best practices to help maintain robust communication in industrial environments.

By the end of this article, you'll have a comprehensive understanding of RS-232. You'll understand its advantages and why it's still relevant in today's industrial landscape.

So, let's embark on this journey to explore the world of RS-232. Let's understand why it continues to be a reliable choice for industrial communication.

Whether you're an engineer, a technical manager, or just curious about industrial communication systems, this article is for you. Let's dive in and explore the advantages of serial RS-232 in industrial applications.

Introduction to RS-232

The RS-232 standard has been an integral component in communication protocols since its inception. Introduced in the 1960s by the Electronic Industries Association (EIA), it was initially designed for telecommunication. Over the decades, it has found use in various fields due to its robustness and simplicity.

RS-232 is often used to connect computers and peripherals. It facilitates the transfer of data between devices through serial communication. While newer technologies like USB and Ethernet have emerged, RS-232 remains a staple in many industrial applications due to its reliability.

Even in today's technology-driven world, RS-232 continues to be favored for industrial settings. Its capability to function in challenging environments makes it invaluable. Furthermore, its compatibility with legacy systems reinforces its enduring presence.

Despite its age, RS-232 has evolved over time. The standard has undergone several updates to adapt to changing needs and technologies. This adaptability ensures its continued relevance in modern communication applications.

Understanding RS-232 involves delving into its technical specifications. Exploring how it functions and interacts with other devices is crucial. The following sections will provide a more detailed look into what RS-232 is and its significance in the industrial realm.

What is RS-232?

RS-232 is a standard for serial communication transmission of data. At its core, RS-232 defines the electrical characteristics and the timing of signals. It also specifies the size and layout of connectors.

The RS-232 protocol allows for communication between a data terminal and data communication equipment. It's a full-duplex protocol, which means it can send and receive data simultaneously. An RS-232 interface usually includes several different signals for control and timing. Common signals include Transmit Data (TXD), Receive Data (RXD), and Ground (GND). Additional control signals, like Request to Send (RTS) and Clear to Send (CTS), manage the data flow. RS-232 ports are available on many older computers and specialized industrial equipment. These ports, also known as serial ports, are often used for direct communication between devices without needing external interfaces.

Though slower compared to modern standards like USB, RS-232 remains an essential communication tool. Its simplicity and low-cost setup contribute to its ongoing use in many systems and devices.

Importance of RS-232 in Industrial Settings

In industrial environments, RS-232's resilience is one of its greatest strengths. It can operate over longer distances compared to other communication standards. This makes it ideal for factory floors and plant operations.

RS-232's ability to connect to a variety of devices makes it versatile. It's commonly used in industrial machinery, POS systems, and automation controls. Its reliability in transmitting data in harsh conditions is unmatched.

Compatibility with legacy systems is another vital advantage. Many industrial devices still rely on RS-232 for their communication needs. This compatibility ensures seamless integration when updating or maintaining existing systems.

Furthermore, RS-232's design simplicity translates to easy troubleshooting and maintenance. This reduces downtime, a crucial factor in high-stakes industrial operations. Therefore, the continued use of RS-232 highlights its lasting value in industrial settings.

Overview of RS-232 Protocol

The RS-232 protocol, though simple, is a model of efficiency. It uses a series of voltage levels to transmit data. Typically, a logic '1' is represented by a voltage between -3 to -15 volts. A logic '0' is indicated by a voltage from +3 to +15 volts.

The data transmission in RS-232 usually follows a structured format. This includes a start bit, followed by a number of data bits, and typically a stop bit. This structure ensures that the receiving device can correctly interpret the signals.

RS-232 employs asynchronous transmission. This means it doesn't require a clock signal to interpret data. Instead, it relies on clear start and stop bits to synchronize the communication. Flow control is an essential part of the RS-232 protocol. It helps manage data transmission and prevents data overflow. Using control lines like RTS and CTS, devices can signal when they are ready to send or receive data.

Despite its simplicity, the RS-232 protocol remains a cornerstone of serial communication. Its enduring presence is a testament to its robust and reliable design, making it a preferred protocol in many industrial applications.

RS-232 Connections

Understanding RS-232 connections is crucial for effective communication. RS-232 setups typically involve various connectors, cables, and signal types. Each plays a role in ensuring smooth data transmission. The connections utilize a standard electrical interface, facilitating interoperability between devices.

The RS-232 interface employs distinct connectors tailored for specific purposes. These connectors ensure electrical compatibility and robust signal transfer. The most common connectors include DB-25 and DE-9, each offering a unique configuration suitable for diverse applications.

In an RS-232 connection, the cable quality and length significantly impact performance. High-quality, shielded cables are preferred to reduce noise and interference. Proper grounding and shielding also protect against environmental noise and signal degradation.

RS-232 connections can manage various devices in industries ranging from telecommunications to manufacturing. These connections are crucial for setting up equipment, configuring machinery, and networking devices. Their reliability makes them indispensable in settings that demand stable communications.

A typical RS-232 setup involves connecting devices using compatible ports and the correct cables. Different port types offer varying levels of functionality and are chosen based on specific requirements. Understanding these differences can aid in selecting the right connections for industrial applications.

Understanding RS-232 Port Types

RS-232 ports, also known as serial ports, come in several forms. Each type serves different functions based on design and compatibility requirements. The most prevalent port types are DE-9, DB-25, and RJ-45. Each has specific configurations tailored for unique needs.

- DE-9: Common in personal computers, offering nine pins with data and control signal capabilities.

- DB-25: Broadly used in older systems, featuring 25 pins for extensive signal exchange.

- RJ-45: Less common but sometimes used with adapters, offering enhanced versatility.

The DE-9 port remains popular in modern applications due to its compact size. DB-25 ports, while bulkier, provide more signal options, making them useful in complex setups. Meanwhile, RJ-45 ports adapt RS-232 for diverse networking scenarios with appropriate converters.

Selecting the right port type involves assessing the communication requirements of the devices involved. Factors such as signal length, data rate, and device support can dictate the choice. A careful evaluation ensures optimal performance and compatibility within industrial systems.

RS-232C Connector Specifications

The RS-232C connector adheres to strict specifications set by the EIA. It outlines various technical aspects such as pin arrangement and voltage levels. These specifications ensure reliable and consistent communication between interfacing devices.

Pin configuration in RS-232C connectors is crucial. Each pin performs a specific function in the communication process. For example, the Transmit Data (TXD) pin sends data, while the Receive Data (RXD) pin receives it. Understanding these roles is necessary for troubleshooting and setup.

Voltage levels in RS-232C are another critical specification. The protocol defines logic '0' and '1' using specific voltage ranges. This helps in maintaining signal integrity over long distances. Consistent voltage levels prevent data errors and ensure accurate transmission.

Compliance with RS-232C specifications helps in achieving interoperability. Devices built to these standards can communicate seamlessly, resulting in efficient data transfer. This compliance also eases the integration of new devices into existing systems.

How to Set Up RS-232 Communication

Setting up RS-232 communication involves several straightforward steps. The process is user-friendly, making it accessible even to those with limited technical knowledge. Proper setup ensures efficient data flow and minimizes potential communication errors.

Initially, select compatible devices and cables. The cables should match the required length and quality to minimize signal loss. Once the devices are connected, check the connector pins to ensure accurate alignment.

Next, configure the communication parameters on both devices. This includes setting the baud rate, parity, data bits, and stop bits. Matching these settings is vital as mismatches can hinder communication. Most devices allow easy parameter configuration through software interfaces.

Finally, test the connection by sending data between devices. Use diagnostic tools or software to verify data integrity and identify potential issues. Adjust the configuration as needed to resolve any discrepancies detected during the test.

A successful RS-232 setup can significantly enhance system performance. It provides a reliable means of communication, fostering improved control and data management in industrial environments.

Advantages of RS-232 in Industrial Applications

Serial RS-232 offers several advantages, making it a preferred choice in various industrial applications. Its simplicity, reliability, and widespread adoption contribute to its enduring relevance. Despite the emergence of modern communication standards, RS-232 maintains a strong presence in industry due to these benefits.

One primary advantage is RS-232's robustness in challenging environments. Its design ensures stable performance even in electrically noisy conditions. Industrial settings often present such challenges, where RS-232's resilience becomes vital. This capability minimizes data loss, ensuring accurate communication.

Additionally, RS-232's simplicity reduces the likelihood of errors during installation and operation. Fewer components and straightforward configurations lower the risk of malfunctions. This results in reduced maintenance requirements, saving time and resources for businesses.

The availability of RS-232-compatible components facilitates easy integration with existing systems. Industries with legacy equipment find RS-232's compatibility with older technologies invaluable. This backward compatibility supports gradual upgrades without extensive overhauls or changes.

A significant advantage of RS-232 is its cost-effectiveness. The technology's maturity and widespread use have reduced the costs associated with its implementation. Furthermore, durable RS-232 components require fewer replacements, contributing to long-term savings for industrial users.

Reliability and Stability

RS-232 is renowned for its reliability, a crucial factor for industrial applications. Its design ensures consistent performance, which is essential for operations that require nonstop communication. The protocol's robustness enables it to withstand fluctuations and interference prevalent in industrial environments.

One key aspect of RS-232's reliability is its ability to maintain data integrity over long distances. Even in noisy conditions, RS-232 can transmit data accurately, thanks to its use of voltage levels to represent signals. This feature significantly reduces the risk of data corruption.

Another reliability factor is RS-232's error detection capabilities. The protocol includes parity checks and stop bits to identify and correct transmission errors. These mechanisms ensure that any data anomalies are quickly identified, maintaining communication accuracy.

The stability offered by RS-232 also contributes to reduced system downtime. With fewer communication failures, industries can maintain continuous operations. This stability is especially crucial in applications like process control, where uninterrupted data flow is essential.

Compatibility with Legacy Systems

Compatibility with legacy systems is a notable advantage of RS-232 in industrial applications. Many industries still rely on equipment developed decades ago, which often utilizes RS-232 interfaces. The ability of RS-232 to seamlessly integrate with such systems is invaluable.

RS-232's compatibility allows industries to extend the life of their existing equipment. Instead of investing in entirely new systems, businesses can retrofit old devices with RS-232 interfaces.

This capability provides a cost-effective solution for maintaining and upgrading legacy systems. Moreover, RS-232 serves as a bridge between modern and older technologies. It facilitates data exchange between old systems and new equipment, ensuring smooth transitions during upgrades. By doing so, RS-232 minimizes disruptions in industrial operations.

Another benefit is the extensive knowledge base available for RS-232. Long-standing use means ample documentation and expertise are available for troubleshooting and maintenance. This wealth of information aids in keeping legacy systems operational with minimal technical challenges.

Cost-Effectiveness

The cost-effectiveness of RS-232 is another compelling reason for its widespread use. Industrial applications often demand economically viable solutions, and RS-232 meets this requirement by offering low-cost communication components and interfaces.

The simplicity of RS-232 leads to reduced installation and maintenance costs. Fewer moving parts mean fewer points of failure, lowering the need for costly repairs and replacements. This reduces the overall cost of ownership for businesses utilizing RS-232 communications.

In addition, the lack of licensing fees associated with RS-232 protocols makes it a budget-friendly option. Industries can implement RS-232 without incurring the additional costs often linked with proprietary technologies. This financial advantage allows businesses to allocate resources to other critical areas.

Finally, the longevity and durability of RS-232 components contribute to cost savings. The components are less likely to fail, reducing downtime and prolonging equipment lifespan. Consequently, businesses benefit from fewer interruptions and enhanced productivity.

RS-232 Communication Protocol

The RS-232 communication protocol is crucial in ensuring efficient data exchange between devices. It defines the standards for serial communication, including signal voltage levels, wiring, and timing. Its simplicity and reliability make it widely used in industrial environments. RS-232 operates using a series of electrical signals transmitted over a communication line.

These signals represent binary data, allowing devices to exchange information. The protocol supports full-duplex communication, meaning data can be sent and received simultaneously. The widespread adoption of RS-232 is partly due to its established set of standards. These standards ensure compatibility and interoperability among different devices. As a result, RS-232 remains a popular choice for connecting a variety of equipment in industry.

A critical feature of the RS-232 protocol is its error detection and correction mechanisms. It incorporates parity bits and checksums to identify transmission errors. These features help maintain data integrity, crucial in industrial applications where precision is key.

Basics of RS-232 Serial Communication

RS-232 serial communication involves transmitting data in a sequential, bit-by-bit manner. The process begins with a start bit to signal the data's transmission. Each byte of data follows, concluded with a stop bit to signify the end of the byte.

Devices using RS-232 must agree on a common communication protocol. This agreement includes aspects such as baud rate, data bits, stop bits, and parity. Baud rate defines the speed at which data is transferred, typically measured in bits per second.

Communication occurs over a single cable with specified voltage levels representing binary 0s and 1s. These levels are typically between +3 and +15 volts for a binary 0 and -3 to -15 volts for a binary 1. This method ensures that devices recognize the incoming signals accurately.

Hardware handshaking is sometimes employed to manage data flow. This mechanism uses control signals to pause or resume data transmission based on device readiness. Effective flow control ensures that neither device becomes overwhelmed by incoming data, preventing data loss.

Data Transmission Rates and Protocol Standards

RS-232 data transmission rates vary, influenced by the selected baud rate. Common rates include 9600, 19200, and 38400 bits per second, though higher rates are possible. The choice of rate depends on the application and the capabilities of connected devices.

The RS-232 standard includes specifications for wiring, connectors, and voltage levels. While initially designed for short-distance communication, its protocols ensure reliable data transmission. Cable length and quality can affect performance, necessitating consideration during setup.

Devices communicating via RS-232 must adhere to these specifications to ensure compatibility. The standard also dictates the use of specific connectors, such as the DB9 and DB25. These connectors facilitate secure physical connections, essential for stable communication.

Despite new communication technologies, RS-232 remains relevant due to its simplicity and ease of use. Its protocol standards are well-documented, providing a robust framework for data exchange. This makes RS-232 a dependable choice for many industrial and legacy systems.

Signal Formats and Flow Control

RS-232 uses well-defined signal formats to ensure clear data transmission. Each byte of data is encapsulated between start and stop bits. These delimiters signal the beginning and end of the data stream, allowing devices to synchronize.

The parity bit is another critical aspect of signal format. It serves as an error-checking feature, helping to identify transmission errors. Configurations can be set to use even, odd, or no parity, depending on the required data integrity levels.

Flow control in RS-232 is vital in managing data transfer. Two primary types of flow control exist: hardware and software. Hardware flow control uses control lines, while software flow control relies on special characters sent within the data stream.

Effective flow control prevents overflow, ensuring that data is transmitted smoothly. It stops data flow when the receiving device's buffer is full, allowing time to process existing data. This feature helps avoid data loss and ensures communication is efficient and precise.

Practical Applications of RS-232

RS-232 has proven invaluable in industrial contexts due to its simplicity and reliability. Its robust design makes it suitable for numerous practical applications. From automation systems to networking devices, RS-232 enables seamless integration and control.

In industrial automation, RS-232 is often used to connect programmable logic controllers (PLCs) with other equipment. This connectivity allows for efficient data transfer and process control. It also aids in monitoring critical manufacturing processes.

Data acquisition systems frequently rely on RS-232 to collect and transfer data from sensors and instruments. This setup enables real-time monitoring and ensures data integrity. It is vital for maintaining optimal operations in various industrial sectors.

Networking devices using RS-232 involves interconnecting various hardware components to facilitate communication. This method allows devices to exchange data without the need for more complex protocols. It provides a straightforward and effective solution for many industrial networking needs.

The versatility of RS-232 extends to many other areas as well. Below is a list of its notable applications in different industries:

- Manufacturing: Facilitates machine communication and quality control.

- Telecommunications: Integrates with modems and switches for data transfer.

- Medical Equipment: Ensures reliable communication in diagnostic devices.

- Point-of-sale Systems: Connects peripherals like barcode scanners.

- Aviation: Manages data within navigation and communication devices.

- Automobiles: Used in diagnostics and testing of automotive systems.

Industrial Automation Systems

Industrial automation systems rely heavily on RS-232 for efficient communication. This protocol provides a reliable means to interconnect various components. Its simple interface allows seamless integration with legacy and modern systems alike.

RS-232 is commonly found in robotics and machinery control. It enables direct communication between central control units and devices. By transmitting commands and receiving status updates, it helps automate complex processes with precision.

Given the harsh conditions in industrial environments, RS-232's robust design is an advantage. It withstands electrical noise and interference, ensuring stable performance. This durability makes it an ideal choice for managing machinery in manufacturing plants.

The ability to support full-duplex communication allows continuous data exchange. This feature is essential in applications demanding real-time control and feedback. RS-232 thus enhances both productivity and safety in automation systems.

Data Acquisition and Control

Data acquisition is a critical function in many industrial sectors. RS-232 offers a simple yet effective way to gather and transfer data. Sensors and instruments equipped with RS-232 interfaces can seamlessly communicate with central systems.

In environmental monitoring, RS-232 connects sensors to data loggers or control units. This setup ensures accurate data collection on parameters like temperature and humidity. Consequently, businesses can maintain optimal conditions for sensitive operations.

Control systems also benefit from RS-232 communication. Process controllers use the protocol to adjust system parameters based on data inputs. This ability to interact with multiple devices enhances process efficiency and accuracy.

RS-232's error-checking capability ensures data integrity. By reducing transmission errors, it guarantees that decision-making is based on reliable information. This reliability is vital in industries where every decision impacts safety and productivity.

Networking RS-232 Devices

Networking RS-232 devices involves creating connections between varied hardware systems. This practice enables coordinated data exchange and device management. Despite the advent of more advanced networking protocols, RS-232 remains relevant due to its ease of use.

RS-232 networks often feature devices such as computers, sensors, and machines linked in a daisy-chain configuration. This setup minimizes cabling, reducing costs while ensuring connectivity. It is particularly useful in resource-constrained environments.

The protocol's standardized interface simplifies network expansion. Adding new devices requires minimal changes, facilitating adaptability. Industrial operations can thus scale efficiently to meet growing demands without significant reconfiguration.

Through networked RS-232 connections, data can be directed to multiple destinations. This feature provides flexibility, catering to diverse operational needs. Whether in manufacturing or process control, RS-232 enables robust and adaptable networking solutions.

Challenges and Limitations of RS-232

While RS-232 offers many benefits, it also comes with certain challenges and limitations. Understanding these constraints can help in making informed decisions about its implementation. Users must be aware of distance, speed constraints, and potential interference. One of the main issues with RS-232 is its limited data transfer speed. This can be a bottleneck in high-demand applications. Additionally, it is susceptible to signal degradation over long distances, affecting data integrity.

Interference from external sources poses another challenge for RS-232. Electrical noise can distort signals, compromising communication reliability. Proper shielding and grounding can help mitigate this, but it adds to the complexity of installations.

Finally, the landscape of communication protocols is evolving rapidly. Modern alternatives to RS-232 offer higher speeds and better interference resistance. It's essential to weigh the benefits of RS-232 against these newer technologies.

Distance and Speed Constraints

RS-232 has inherent limitations in terms of distance and speed. It is designed for short-distance communication, typically up to 15 meters. Beyond this, signals may degrade, leading to data loss or errors in transmission.

The data transmission speed of RS-232 is another limitation. Its maximum speed is relatively low, usually around 19.2 Kbps to 115.2 Kbps. In contrast, modern protocols can achieve much higher throughput, making RS-232 less suitable for high-speed applications.

These constraints make RS-232 less appealing for new installations requiring high bandwidth or long-distance communication. However, for applications where moderate speeds are adequate, RS-232 remains a viable option. Proper cabling and hardware can mitigate some of these limitations. Yet, users should be aware of the operational conditions to ensure reliability.

Interference and Signal Degradation

RS-232 is prone to interference and signal degradation, particularly in electrically noisy environments. This susceptibility can lead to errors and unreliable data transmission. Devices in industrial settings often produce substantial electrical interference, which can distort RS-232 signals.

The protocol operates using voltage levels to convey information. Any external noise can affect these voltage levels, causing communication errors. Shielded cables and effective grounding are crucial to minimizing interference. However, these solutions can complicate system setups and increase costs.

Signal degradation can also occur due to poor quality cables or improper connections. Ensuring the use of high-quality materials and correct installation practices helps maintain signal integrity. While RS-232's simplicity is appealing, these considerations should not be overlooked to ensure stable operation.

Modern Alternatives to RS-232

With technological advancements, several modern alternatives to RS-232 have emerged. These alternatives offer higher data rates and improved noise immunity. Protocols like USB, Ethernet, and RS-485 have become increasingly popular in industrial applications.

USB provides high-speed data transfer and ease of connectivity, surpassing the limitations of RS-232. It offers plug-and-play functionality, which simplifies device installation and management. This convenience has made USB a preferred choice in many sectors.

Ethernet is another powerful alternative, offering extensive networking capabilities and high data rates. Its ability to cover long distances without significant signal degradation makes it ideal for large-scale operations.

Lastly, RS-485 is similar to RS-232 but supports longer cable lengths and more nodes per network. It also has better noise resistance, making it suitable for industrial environments. When considering alternatives, it's essential to assess the specific needs of your application. While RS-232 remains relevant, modern protocols may offer advantages worth exploring.

Conclusion

In industrial applications, RS-232 continues to hold significant value. Its simplicity and reliability are unmatched in many scenarios. Despite modern alternatives, RS-232 remains a strong contender for specific roles.

The longevity of RS-232 is attributed to its proven track record. Industries rely on its stable performance for critical tasks. Moreover, its compatibility with legacy systems provides a seamless integration pathway.

While it faces challenges from newer technologies, RS-232 has distinct advantages. Cost-effectiveness, ease of use, and widespread adoption cannot be overlooked. It offers practical solutions for many industrial needs.

Future of RS-232 in Industrial Applications

Despite advancements in communication protocols, the future of RS-232 remains promising. Its unique blend of simplicity and reliability ensures continued relevance. As industries evolve, RS-232 adapts to new technological landscapes.

Industrial environments still benefit from RS-232's robust features. It serves vital functions where modern alternatives may not be optimal. Moreover, innovations continue to integrate RS-232 with contemporary systems.

As industries modernize, RS-232 complements newer protocols. Hybrid systems utilizing RS-232 and other technologies emerge. This creates efficient communication networks, marrying the old with the new.

Summary of Key Advantages

RS-232 offers several key advantages that make it appealing. Its reliability in data transmission is second to none. By minimizing errors, it ensures accurate communication in challenging settings.

Cost-effectiveness is another major benefit. RS-232 systems do not require expensive components or complex installations. This makes them ideal for budget-conscious projects. Compatibility with legacy systems further enhances its value. As industries transition, RS-232 provides a reliable bridge. Its widespread use means support and resources are easily available.

Ultimately, RS-232 continues to be a vital part of industrial communication. Its advantages make it an enduring choice for many applications. The balance of performance and simplicity ensures its place in the future.

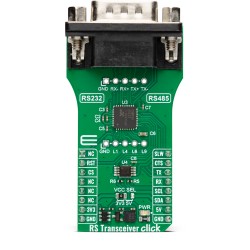

RS-232 in Action: Products & Projects

Curious to see how RS-232 is used in real-world scenarios? We've got you covered.

Explore our selection of RS-232 Click boards™ – ready-to-use modules that simplify serial communication integration. Perfect for adding robust, industrial-grade connectivity to your next project.

Want to see RS-232 in practice? Dive into hands-on projects on EmbeddedWiki. Discover how engineers and makers are using RS-232 in automation, data logging, device interfacing, and more. Whether you're looking for inspiration or step-by-step build guides, it's all just a click away.

ABOUT MIKROE

MIKROE is committed to changing the embedded electronics industry through the use of time-saving industry-standard hardware and software solutions. With unique concepts like Remote Access, One New Product/Day, Multi-Architectural IDE and most recently, the EmbeddedWiki™ platform with more than million ready-for-use projects, MIKROE combines its dev boards, compilers, smart displays, programmers/debuggers and 1800+ Click peripheral boards to dramatically cut development time. mikroBUS™; mikroSDK™; SiBRAIN™ and DISCON™ are open standards and mikroBUS only has been adopted by over 100 leading microcontroller companies and integrated on their development boards.

Your MIKROE

RS232 Click

RS232 Click  RS232 2 Click

RS232 2 Click  RS232 3 Click

RS232 3 Click  RS232 Isolator Click

RS232 Isolator Click  RS232 Isolator 2 Click

RS232 Isolator 2 Click  RS232 SPI Click

RS232 SPI Click  RS232 to I2C Click

RS232 to I2C Click UART MUX Click

UART MUX Click UART MUX 2 Click

UART MUX 2 Click UART MUX 4 Click

UART MUX 4 Click  M-Bus Master Click

M-Bus Master Click  M-Bus Slave Click

M-Bus Slave Click  UART I2C/SPI Click

UART I2C/SPI Click  RS Transceiver Click

RS Transceiver Click